Glass processing ERP management system is dedicated to the customized glass temper factory, covering all the functions required for the factory production management, from the implementation of the customer quotation, receiving orders, production (including cutting, edging, drilling, washing, tempering, laminating, sandblasting, insulating, storage process and damaged patch), the finished glass delivery; on the other hand, to achieve the sales performance statistics, work piece statistics, production scheduling and production schedule query; also the corresponding customer receivables, effective management of customer debt situation and so on.

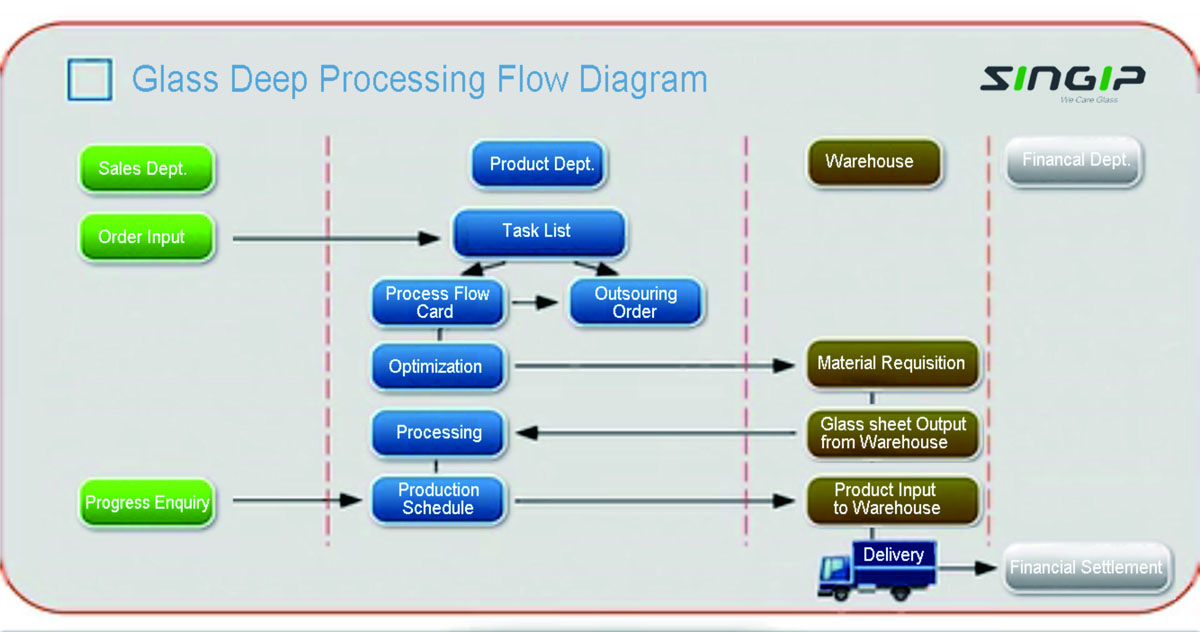

1. Glass processing flow diagram:

2.Network topology map

3.Barcode with scan system: